There are a number of changes coming to the NTT INDYCAR SERIES for 2023, specifically to the rear of the cars.

A collaborative effort between INDYCAR and official chassis supplier Dallara sees the redesign and introduction of a new rear attenuator, with a focus on improved safety with greater crushability to reduce the amount of force felt in the cockpit from impacts with the back end of the car.

“We finished the work on this latest attenuator approximately 18 months ago, so rather than just waiting until we release the hybrid, we brought it forward,” said Tino Belli, director of aerodynamic development for INDYCAR. “We've had to update the gearbox mount a little bit. It was designed to go with the gearbox casing that was going with the hybrid. So, now we've just managed to re-engineer such it will work on the current gearbox casing.”

The new attenuator is designed to decrease peak G-force levels. It is the continued evolution from data collected from the original DW12 attenuator, which was originally a closed box that underwent a couple of modifications over the past decade. The most significant previous update came during the 2016 season, when some drivers complained of headaches after backing into the wall on street circuits.

“We reworked existing attenuators, and we removed the back bulkhead so it would crush easier at the tips,” Belli said. “We went in and thinned the material right at the very back so that the initial impact was much softer. It's just that they (drivers) had a bit of a headache. And we don't want them to even have a bit of a headache, if possible. And so that got evolved and then we were working on this one.

“The whole concept is to try and bring the peak G's down, make them even lower and even spread the crush over a longer distance. This attenuator is longer than the one we have now. Dallara's FEA – Final Element Analysis – of crushing structures has got much better over the years, so they were able to model it much better virtually before we took it to an impact test.”

The new attenuator is approximately 110 millimeters (4.3 inches) longer than the previous one, but is actually lighter by roughly 1.5 pounds. Sled tests that resulted in the product being crushed showed average and peak decelerations of the new attenuator to be much lower than that of its predecessor.

The new attenuator is approximately 110 millimeters (4.3 inches) longer than the previous one, but is actually lighter by roughly 1.5 pounds. Sled tests that resulted in the product being crushed showed average and peak decelerations of the new attenuator to be much lower than that of its predecessor.

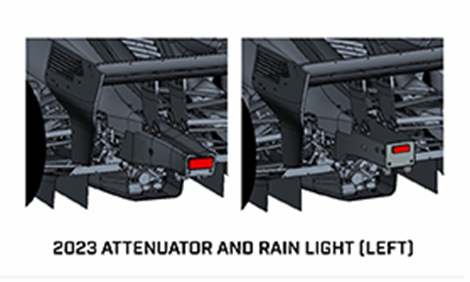

Bigger pins will hold the new attenuator to the back of the gearbox, which will help the unit work more effectively in rear impacts on ovals. Additionally, the back of the cars will be equipped with more visible LED rain lights.

“At one stage we put a camera in the back there – I think that was when we did the '18 kit – and the camera never really got used very much,” Belli said. “It was a panning camera, which it never panned because the vibrations were too much for it. That got removed two seasons ago. Now, because we reworked it, we've taken advantage and used this space to go for a bigger rain light so that if we have a situation like the GMR Grand Prix last year, the more lights we can get out there when there's a cloud of mist, the more chance the drivers got to see in it. So, we've increased that.”

Another new safety feature on the cars for this year is stronger rear-wheel tethers, properly known as the EMS (Energy Management System).

“We took the opportunity to increase the strength of the rear wheel EMS (Energy Management System),” Belli said. “We have the same number of EMS; we just made each bundle bigger, which has increased the strength by about 30 percent. Over the years we've observed a few cases where the rear wheel EMS had not managed to hold the rear wheel and upright assembly to the vehicle in an accident. We thought while we are designing a new gearbox casing for the hybrid, we should design it to accept higher strength EMS. Always trying to get better.

“Then when the hybrid program got delayed, we went back and we said, 'Hey, can we make these EMS fit the current gearbox?' To retrofit them, we had to change the design of the ends of the EMS a little bit from what we had used for years. As we always do, we did pull tests to check out the new EMS, and we found that the new end design was better than the old. The retrofit made us put our thinking caps on and produce an even better solution.”

Overall, Belli and his staff have used years of data and experience to help further the safety innovations in the NTT INDYCAR SERIES.

“That's a good thing about redesigning components is what you think that you've got to the maximum in the past,” he said, “you relook at it and sometimes with new technologies and just more knowledge, you find that actually you can make it even better.”